Everything you need to choose a chess table — from sizes & ergonomics to wood species, epoxy vs wood inlay, bases, and mounting. This guide highlights three unique ChessboArt paths: a custom epoxy inlay service on your furniture, a bespoke chess table commission, and our professional modular Bughouse table.

Updated:

Quick picks

- Most popular chess table: 55–60 mm squares for 3.75–4.0″ kings (tournament feel), walnut or ash, readable coordinates.

- Modern statement: epoxy inlays for high contrast and visual depth.

- Classic look: wood inlay (intarsia) with a subtle, timeless finish.

- Events & clubs: modular Bughouse table — fast to transport, pro layout, space for clocks.

Custom Epoxy Inlay — service on your furniture

Own a solid-wood tabletop, console, or shelf and want a permanently integrated chessboard? Our Custom Epoxy Chessboard Service combines CNC-engraved squares & notation, a precise epoxy resin pour, and a full-surface sand & hand finish so the whole area is perfectly flat, durable, and beautiful.

- Starting at: €280 (standard configuration).

- Square sizes: typically 40 mm; custom from ~24–76 mm on request.

- Epoxy colors: pearl white or black by default; custom tones available.

Bespoke Chess Table — full commission

Prefer a made-from-scratch chess table? Our Bespoke Commission is a transparent, four-step collaboration:

- Size. Select the square size (≈24–56 mm; larger on request) and proportion the tabletop for comfort. We usually recommend ~740 mm width and ≥900 mm length to leave room for a clock and notation.

- Wood. Solid hardwoods: dark (American walnut, iroko, acacia) or light (ash, oak, beech, mango).

- Board technique. Epoxy resin (our signature), wood inlay (classic), traditional joinery, or DGT/electronic integration with hidden cable channels.

- Base. We can source steel “spider legs” or adapt to your base (stability + logistics).

Professional Modular Bughouse table

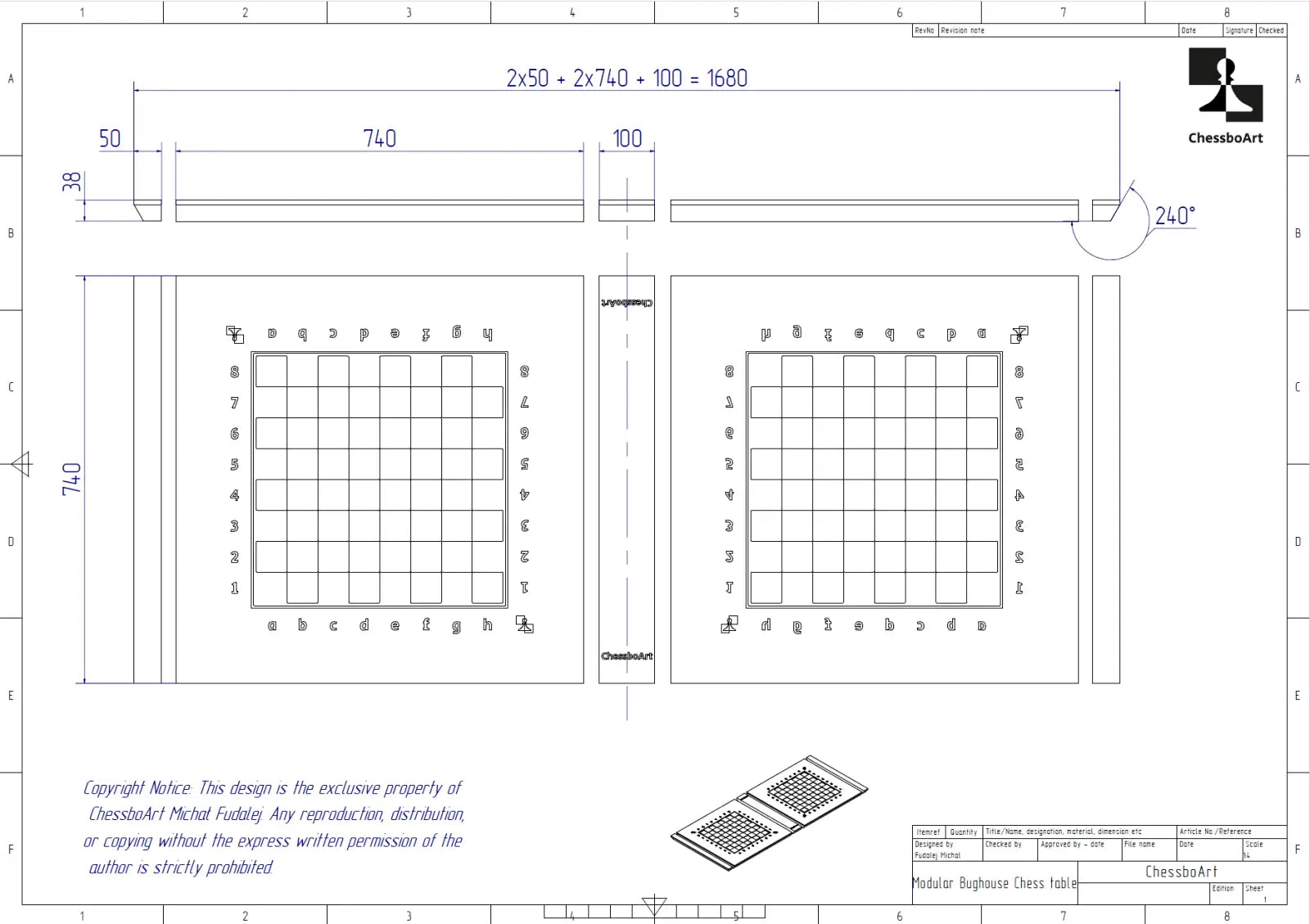

When the Global Chess Festival needed a world-class solution for Bughouse, we designed a new standard: a 5-piece modular tabletop that converts between Bughouse and standard play, packs down for transport, and provides dedicated space for chess clocks.

- Iroko hardwood with pearl-white epoxy inlays.

- 56 mm squares (comfortable for fast, team play), top thickness ~38 mm.

- Overall: 150 × 75 cm; modular, bolted construction; scalable for event layouts.

Sizes & ergonomics

For natural proportions, target a king base covering ~73–78% of a square. Use this quick matrix to match your pieces and board:

| King height | Square size | Staunton | Board width | Best for |

|---|---|---|---|---|

| 3.25″ | 45–50 mm | No. 4 | ~38–42 cm | Compact desks |

| 3.5″ | 50–54 mm | No. 4–5 | ~42–45 cm | Home setups |

| 3.75″ | 54–60 mm | No. 5 | ~45–50 cm | Training |

| 4.0″ | 60–64 mm | No. 6 | ~50–55 cm | Tournament feel |

Table height: aim near ~74 cm (±2 cm) for chairs/sofas. For a chess coffee table, smaller 50–55 mm squares keep proportions comfortable at lower seating heights.

Tabletop dimensions: A board is more than its squares. For a comfortable experience, you need "breathing room." We recommend a minimum width of ~740 mm (74 cm) and a length of at least ~900 mm (90 cm). This provides stable, dedicated space for a tournament clock, a scoresheet, a drink, and room to rest your arms during a long game without crowding the board.

Materials & finishes (epoxy vs inlay)

The choice of material and technique defines the character of your table. We work exclusively with solid hardwoods, never veneers, to ensure a lifetime of durability.

Wood Species:

- American Walnut: A premium classic. Its deep, chocolate-brown color provides a luxurious contrast for pearl-white epoxy or a traditional maple inlay. Excellent stability and timeless appeal.

- Ash: A very hard and durable European wood. Its bright, creamy grain creates a stunning, high-contrast modern look when paired with black resin. A favorite for minimalist and Scandinavian-style interiors.

- Iroko: An extremely dense and heavy African hardwood. Its high oil content makes it incredibly durable and stable, perfect for high-traffic environments like clubs or our event-grade Bughouse table.

- Oak, Acacia, Mango: We also frequently work with these species, which offer classic tones and wonderfully expressive grain patterns.

Epoxy Resin vs. Wood Inlay:

This is a choice of feel and aesthetic. Both techniques are available on Bespoke Commissions.

- Epoxy Resin (Our Signature): This technique offers a perfectly flat, seamless, 'glass-like' playing surface. It's modern, bold, and very easy to clean. Our process involves precision CNC engraving, pouring the resin, and then meticulously hand-sanding the entire surface to ensure the resin is perfectly level with the wood. It allows for high-contrast, modern designs.

- Wood Inlay (Intarsia): The timeless, traditional method. You can feel the subtle texture of the wood grain on every square. It's a quieter, more classic aesthetic. An inlay board requires waxing or oiling to maintain its luster, just like the rest of the table.

Bases & mounting

We believe in flexibility, which is why we treat our tabletops as a distinct component. This gives you maximum control over the final look and budget. All our tops are pre-drilled (or can be) for straightforward assembly.

- Use Your Own Base: If you already have a base, we can drill mounting points to match your specifications.

- Sourced Steel Legs: For a proven, modern aesthetic, we recommend heavy-duty steel bases (such as "spider" or trapezoid legs). They provide excellent stability for our heavy, solid-wood tops.

- Logistics: Sourcing legs from a specialized partner and shipping them separately from the tabletop is often the most secure and cost-effective method for transport, ensuring everything arrives safely.

Photo gallery

Build your complete setup

Custom Epoxy Inlay service · Bespoke chess table commission · Professional Bughouse table

Shop chess table tops and choose legs & bases

FAQ

What square size fits a 3.75–4.0″ king?

Use 55–60 mm squares; target ~73–78% base-to-square coverage.

Can you integrate a board into my existing table?

Yes — that’s exactly what our Custom Epoxy Inlay service does (CNC + epoxy + full refinishing).

Do you support DGT/electronic boards?

Yes — we can recess DGT/electronic boards in a bespoke build and route hidden cable channels.

Is there a professional Bughouse table?

Yes — our modular Iroko Bughouse table was engineered for event play and easy transport.